One-Stop Solution for Injection Molding & Plastic Products

Product Center

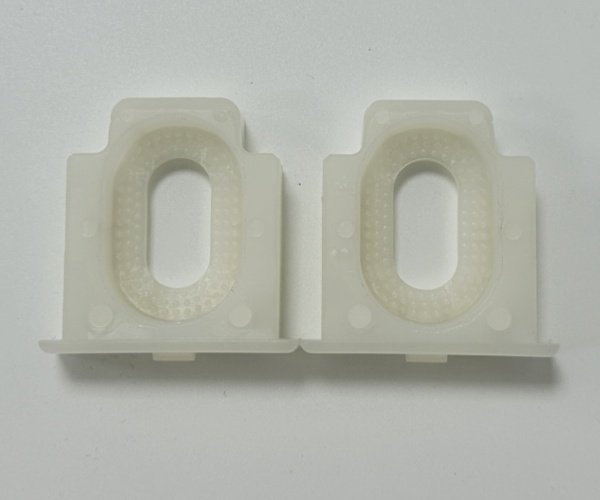

Custom Plastic Injection Molding

Rapid Prototype

Other Services

Plastic extrusion is a cost-effective solution because of its high capacity and low tooling cost.

The blow moulding process produces thin-walled, hollow plastic containers which can be used for a wide variety of applications.

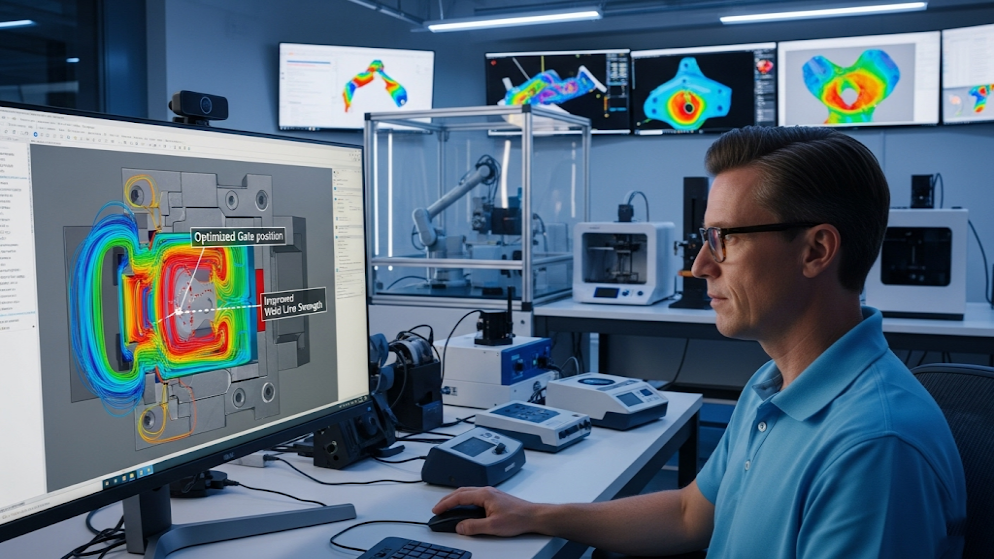

Choosing the right injection molding manufacturer

→Wide range of the best injection molding equipment from 80 tonnages to 1400 tonnages;

→Semi-Automated Work Cells: servo robotics, vision systems;

→Complete QualityControl & Inspection;

→Processing expertise with a wide range of plastic injection materials;

→Experienced plastic injection engineering team provides professional solutions

Custom Solutions for

Every Partner

As a brand owner, are you looking for custom plastic products?

Are you also searching for a reliable supplier that combines stable production capabilities with competitive pricing? Partner with us—you’ll not only get high-quality custom plastic products, but also solutions that precisely match the core needs of your clients, ensuring worry-free delivery for every order.

Are You A Manufacturer or Factory Needing Custom Plastic Parts or Molds?

Looking for a tailored, full-process solution? From high-precision mold manufacturing to efficient, scalable injection molding—each service is tailored to your specific production needs, ensuring production success and fueling business growth.

Are You A Distributor, Wholesaler, or Sourcing Agent?

Looking for a trustworthy supplier with strong production capacity and competitive pricing? Partner with us to meet your clients' custom plastic product needs.

Are You A Product Designer, Engineer, or Startup Founder with an Idea?

From concept to production, we bring your ideas to life with design optimization, precision mold development, and scalable manufacturing.

Why You Should Choose us to use plastic injection moulding for Your Next Manufacturing Project

Flash, also known as burr or flashing, in injection molding refers to the excess material that appears at the parting line or opening of the mold.

In the injection molding process, material flow marks are a common surface defect

shrinkage refers to the phenomenon where the volume of plastic products decrease

Short Shot refers to a common defect in the injection molding process where the molten plastic fails to completely fill the mold cavity, resulting in an incomplete part or missing sections of material.

Common Issues of Gas Traps

Gas traps refer to the phenomenon in the injection molding process where air or other gases are trapped inside the mold cavity and cannot be effectively expelled.

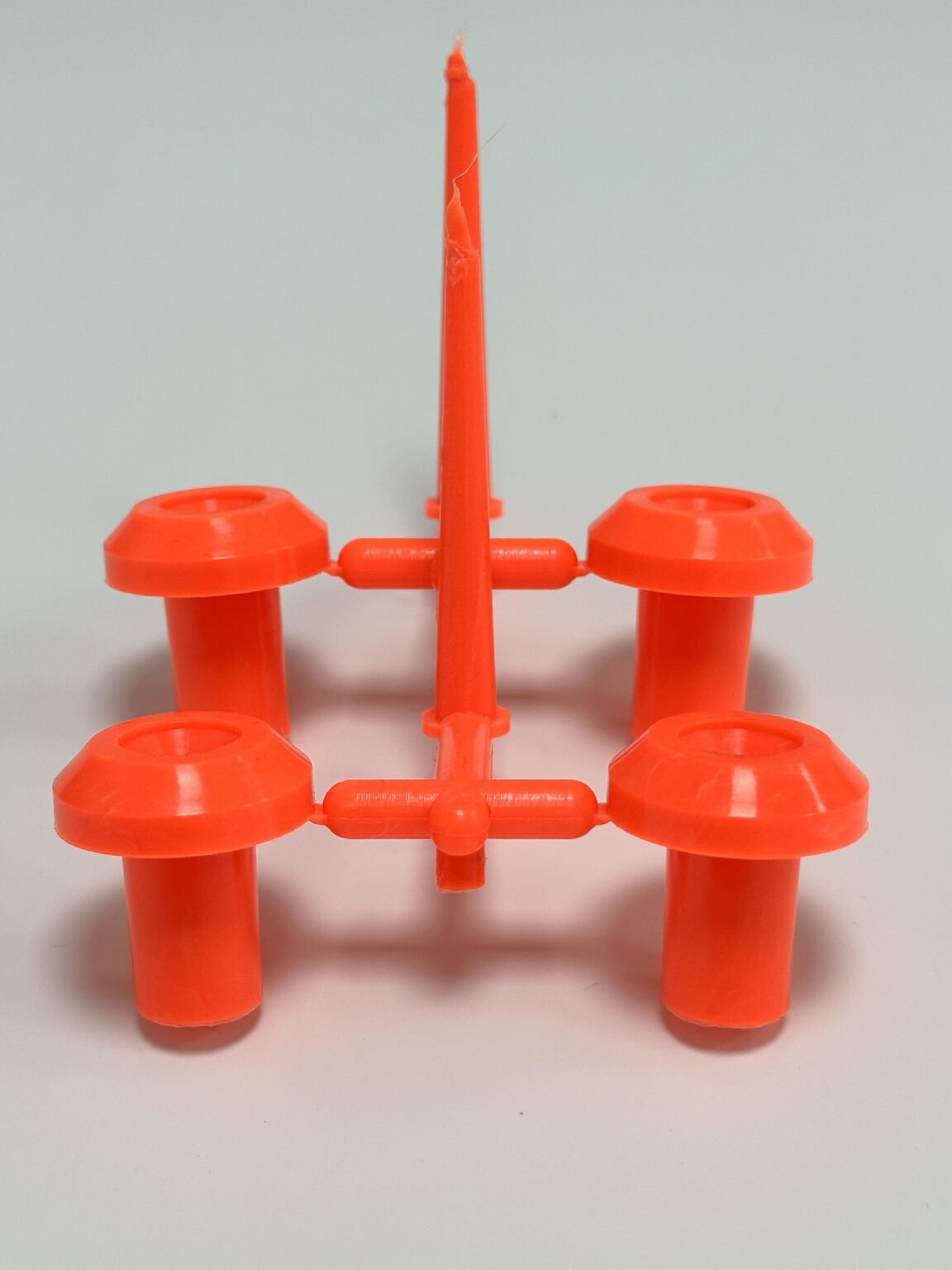

Weld Lines: An Unavoidable Issue

Weld lines are linear defects formed during the injection molding process when molten plastic flows and rejoins in the mold.

If you place an order now, you will enjoy the following free services:

1, Free design improvement suggestions or modification;

2, Free simple DFM report;

3, Free VDI texture catalogue can be shipped by your courier account;

PROTOTYPING & MANUFACTURING

Our Certificates and Patents

Testimonial

Client Feedback & Reviews

Get In Touch

Get in touch and let us know how we can help.

No.50, Liheng Industrial Zone, Xinglin West Road, Jimei District, Xiamen, China

marketing@chinaruicheng.com

WhatAPP : +8615980769781